What is cold chain?

The term ‘cold chain’ describes the movement of temperature-sensitive materials within a connected logistics network at a specific temperature range. When answering the question, ‘what is cold chain?’ it’s helpful to think of a biopharmaceutical therapeutic trial, which involves moving temperature-sensitive biologics between a laboratory, a manufacturer, and a designated space for human trials.

Whether this chain is local (within a city, region, or state), national, or even international, the same principles apply: the biologic payload must be transported throughout this connected chain without significant temperature changes.

The bricks and mortar links in these chains (labs, manufacturing plants, healthcare facilities etc.) need to be supplemented by transport links (couriers, haulage, cargo planes, etc.), all of which must be equipped to carry the relevant hardware (fridges, freezers) to ensure your payload stays within its required temperature range. Combining these bricks and mortar and transport links and keeping a shipment within a specific temperature range constitutes a working cold chain.

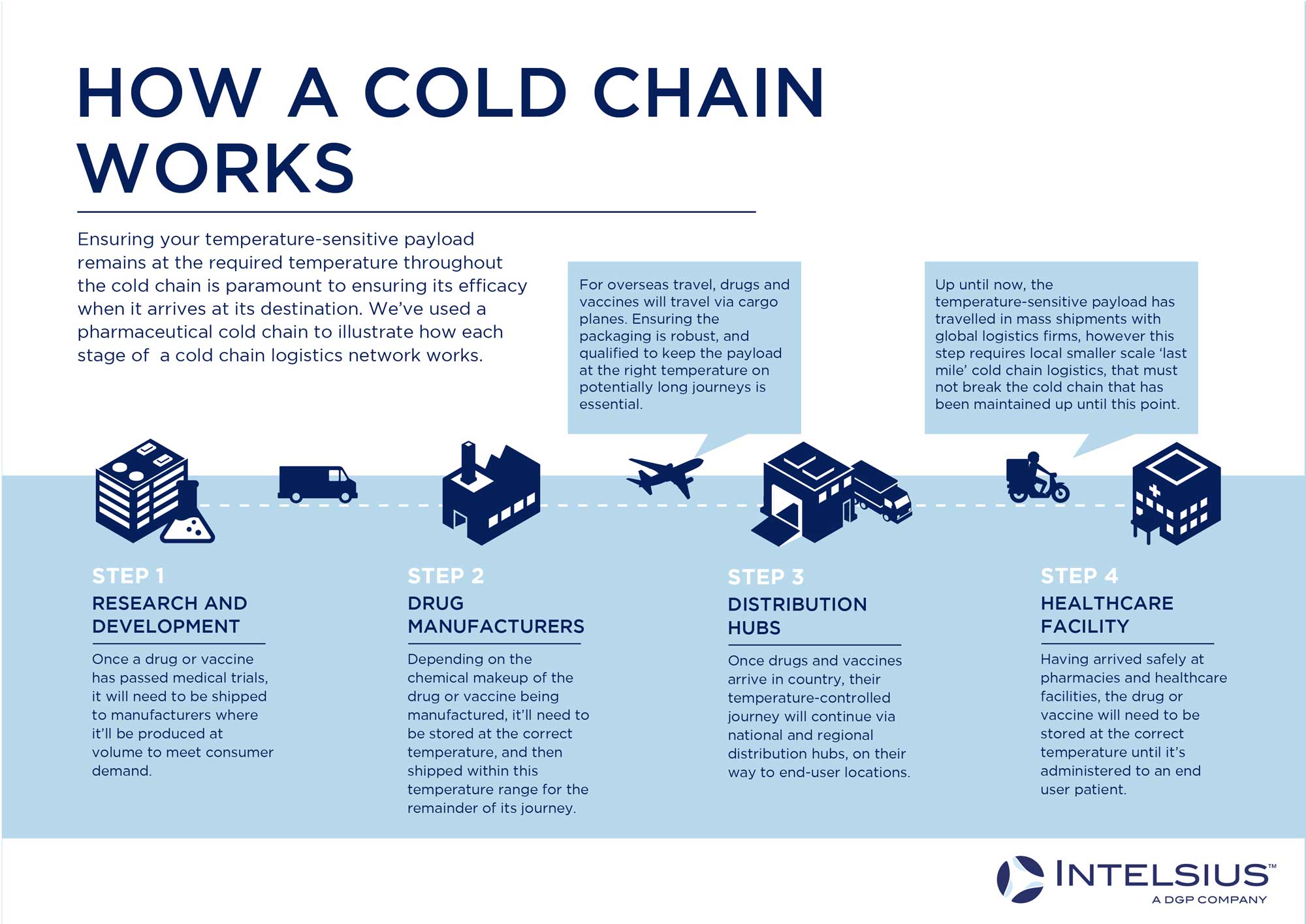

The infographic below outlines how a cold chain works.

What is the cold chain process?

All cold chains are different depending on the payload and how and where it’s being shipped. For example, the above infographic outlines an international cold chain for pharmaceutical products, which involves four key steps connected by international, national, and local logistics networks.

In many cases, the company handling the transportation of a temperature-sensitive payload will change from location to location, so ensuring your payload is shipped adequately within a specific timeframe is essential.

Before sending your product or samples from one location to another, it would be helpful to ask yourself the following questions:

1. Is my product/sample temperature sensitive?

2. If so, what temperature range does it need to stay within to retain its efficacy?

3. How far am I sending it, and how long will this take?

4. Do I have the relevant temperature-controlled packaging to last the entire journey within the relevant temperature range?

5. Is where I’m sending my product/sample reachable with existing logistics networks and providers?

As technology finds its way into cold chain logistics, more and more companies are using connected packaging to track where their payload is at all times and whether it remains within the required temperature range. For full peace of mind, we recommend using connected solutions such as our ORCA Connect temperature-controlled packaging.

What is last mile delivery?

Last mile delivery involves the last step in any cold chain logistics network; the local courier often takes a temperature-sensitive payload to its final destination. However, last mile delivery can become very tricky depending on where you want your product or samples to end up.

Even in a well-established cold chain logistics network, last mile delivery presents the most considerable risk to the payload, as it will likely involve much smaller, local couriers delivering small batches of your payload to its final destination. Therefore, how it’s handled at this stage is essential to ensuring the efficacy of your payload.

However, last mile delivery becomes uniquely challenging when shipping temperature-sensitive samples to locations without well established cold chain logistics and local courier networks and will require additional planning to ensure a successful journey.

The below infographic outlines last mile delivery for COVID-19 vaccines, including the potential end destinations and transport types involved.

How is a cold chain different from a cool chain?

Not to be confused with the term ‘cool chain’, which describes the same linked chain, but with the sole objective of stopping a payload from overheating, cold chain logistics must keep the product within a specific temperature range and involves added complexities such as the length of a journey, the external temperatures, and the cold storage capabilities within the network.

Cold chain compliance

Depending on what temperature-sensitive product or sample you’re shipping, you’ll need to adhere to rules and regulations overseen by various international bodies.

The European Agreement concerning the International Carriage of Dangerous Goods by Road (known as ADR), and The International Air Transport Association (known as IATA), which supports aviation with global standards for airline safety, security, efficiency, and sustainability, are the two main bodies overseeing and enforcing the shipping of dangerous goods through global cold chains.

To read more about achieving UN Category A and B compliance, you can read our helpful UN3373 Compliance Guide here.

Temperature-controlled packaging

As mentioned earlier in the article, to successfully link a cold chain together, you need to use high-quality, compliant temperature-controlled packaging solutions that are the correct size and qualified to correct temperature range and duration for your payload.

Partnering with a packaging expert who understands all the risks involved is essential in successfully shipping your temperature-sensitive payload from A to B. Temperature-controlled packaging such as our ORCA cold chain solutions have been specifically designed to transport temperature-sensitive payloads through even the most extreme shipping lanes for a minimum of 96 hours. Click the button below to explore our full range of ORCA temperature-controlled packaging.

You can explore all our temperature-controlled packaging solutions by clicking the button below.

Alternatively, get in touch with a member of our dedicated Customer Service Team to discuss your packaging needs further.