Can the Internet of Things (IoT) improve cold chain logistics? If so, how? And what are the risks?

If you work in cold chain logistics, you’ll be acutely aware of the value of a well-connected, up-to-date and secure data stream. When, where, and in what condition did your payload arrive are some of the key questions traditionally answered by manual, human processes. However, the emergence of the Internet of Things is changing how we think about supply chain and logistics management. Utilising live, instant, access-on-demand data is the best to manage a secure, cost-effective, and environmentally friendly supply chain.

In this article:

- What is the Internet of Things?

- How could it benefit your cold chain?

- What are the risks?

- Intelsius IoT cold chain packaging solutions

- ORCA Cloud

What is the Internet of Things?

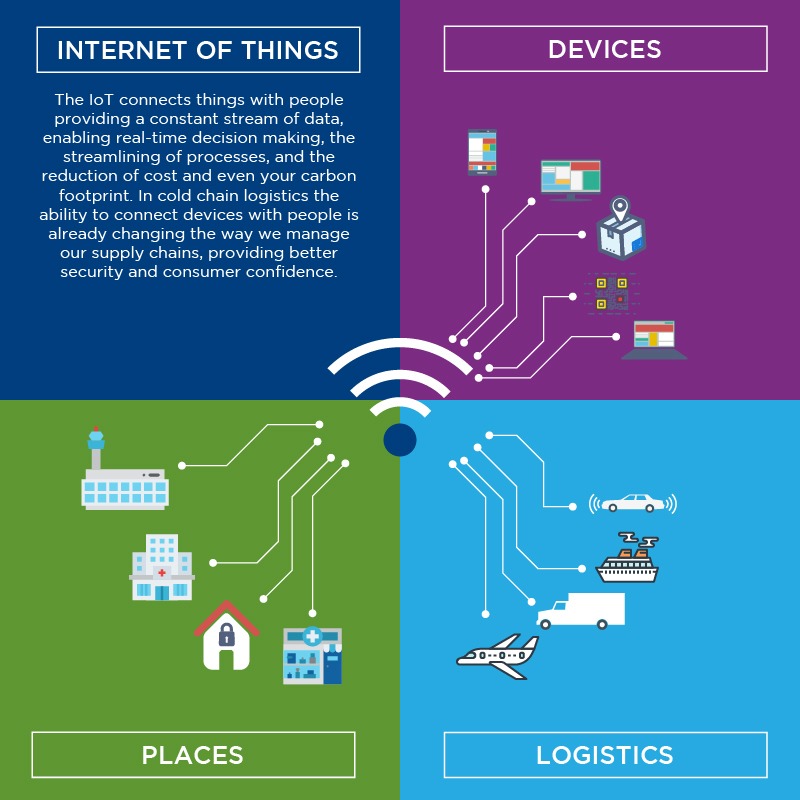

The Internet of Things is a device or number of devices connected by the internet feeding a constant stream of data to each other and/or people that influences real-time decision making. E.g., in consumer IoT, your ability to control the temperature of your house with a mobile app.

The Internet of Things can be both small (one person and one device) and large (thousands of devices and people) in scale, but it is always a network of connected things (devices, appliances, products) and people. When a ‘thing’ is fitted with a sensor or another similar device capable of sending certain data types either live or at programmed intervals, a person who has access to this data via an app, website, or secure data sharing platform can monitor anything from location, internal and external temperature (in the case of cold chain logistics) and whether or not something was opened, compromised, or even stolen.

The Internet of Things enables people to remove unnecessary, often clunky manual processes from their supply chain or production processes, creating constant streams of data that can influence instant, automated decisions, or provide people with vital information about the health or success of their supply chain.

How Could the Internet of Things Benefit Cold Chain Logistics?

We all benefit from Consumer IoT in our day-to-day lives, whether it’s monitoring the heat of our home or employing app-based home security software that allows us to monitor sensors activated by movement or doors being opened when we’re at work or on holiday.

In Commercial IoT, while the idea of a person being fed live or regular data from a sensor or number of sensors is the same, the potential scale and complexity of the provided data are increased. So how could this benefit cold chain logistics? We’re fortunate to partner with world-leading providers of IoT cold chain solutions. Watch our video in which the CEO and Co-founder of data logger experts, Logmore talks about the value of a connected cold chain logistics network.

We’ve taken a further look at three clear benefits of using an Internet of Things connected cold chain logistics network:

1. Security

In a non-IoT supply chain, items (things) are recorded at various stages of their journey: initial send out from manufacturer/warehouse, arrival and departure from next stage logistics hubs such as docks or airports, and arrival at their final destination. These checkpoints typically have real people noting the coming and going of goods, with logistics providers keeping their own records and receipts so the successful delivery of an item can be accounted for.

This manual process of checking in and out, keeping logs, and sending receipts is easily compromised and relies on people doing the right thing at each stage of your payload’s journey. There’s also no way for you or your customer to know whether packaging remained sealed or at its optimum temperature between checkpoints. Once it’s sent, your payload is effectively in the dark, as are you.

Cargo theft accounts for between $15 and $30 billion in stolen supply chain goods each year in the U.S. alone. These thefts are often planned and carried out by highly organised gangs. Whether it’s stolen trucks or temperature-controlled vehicles, or stationary cargo being stolen from depots, ports, or other storage hubs, the need for technological intervention is clear.

Cargo theft accounts for between $15 and $30 billion in stolen supply chain goods each year in the U.S. alone. These thefts are often planned and carried out by highly organised gangs. Whether it’s stolen trucks or temperature-controlled vehicles, or stationary cargo being stolen from depots, ports, or other storage hubs, the need for technological intervention is clear.

With an IoT cold chain, your packaging is sending you/a data hub constant or regular data updates about several things, including location, whether it’s been opened, internal and external temperature, who had handled it and where. This means you can see issues as they arise, alerting local law enforcement or on-site security. It also allows you to pinpoint hotspots, increase security, or change when and where you ship your payload. Lastly, live GPS data means that stolen goods can be tracked, leading to prosecutions, but more than that, create a global deterrent that prevents future payloads from being compromised by organised gangs or individuals.

2. Consumer Confidence

Related to but different to cold chain security, consumer confidence is vital when delivering high-value pharmaceutical products through international cold chains. Has your payload been compromised? Is the payload spoiled? The ability to constantly track key metrics: onboard and external temperatures, when and where the packaging was opened and who opened it are essential questions that IoT allows us to answer.

With spoiled pharmaceutical cargo costs reaching $35 billion each year, being able to guarantee the security and efficacy of your customer’s payload is an invaluable asset when offering your cold chain services to new or existing partners, and the Internet of Things gives you answers to previously unanswerable questions.

3. A More Environmentally Friendly Cold Chain

Packaging, temperature-controlled vans and road, sea and air-fuel usage are all major carbon producers in cold chain logistics. Like all industries, cold chain logistics is on the road to carbon neutrality and needs to look at every available solution to help cut its emissions.

So how could live data create a greener supply chain? A couple of ways:

a) One of the main strengths of the Internet of Things is the ability to analyse huge quantities of data and visualise it in a way that was previously impossible. As such, you can see opportunities to automate or streamline processes – this could involve remapping your logistics legs or making a previously human-led process an automated one, influenced purely by live data sent from sensors.

b) As noted above, spoiled cargo is a major issue in cold chain shipping. In 2019, temperature failures cost the biopharmaceutical industry an estimated $35 billion. These spoiled shipments mean extra logistics legs across the road, sea and air, which means additional carbon emissions. With an IoT connected logistics network, cold chain providers can better monitor these temperature failures, isolate them, and eradicate them through good management and intelligent design.

What are the Risks?

As outlined above, the main focus of IoT has been to streamline processes and reduce costs and carbon emissions. Its potential to revolutionise all industries in these respects is clear.

However, whether it’s your home wireless internet, your employer’s private staff intranet, or a global IoT network, the nature of wireless connectivity makes it open to security issues. A key challenge for the en masse rollout of IoT in supply chain or cold chain logistics is ensuring we don’t swap one challenge for another and open ourselves up to data security threats, which could, in theory, cost companies millions in charges (in the case of European GDPR breaches), or ransomware attacks that demand money in return for private data.

If we’re to offer increased consumer confidence through live data oversight, we also need to ensure this live data is encrypted, and then wirelessly connected things such as packaging, vans or logistics hubs are built with security not only in mind but at the forefront of development.

Intelsius IoT Packaging Solutions

At Intelsius, we refer to Internet of Things packaging as connected packaging; essentially, they achieve the same thing, giving you live or regular data updates from a sensor attached to the packaging. These sensors can tell you the following:

- Packaging location

- Onboard temperature

- External temperature

- Whether the packaging has been opened

- Shock

- Onboard battery life

Below you can watch the CEO and Co-founder of data logger experts, Tec4Med, talk about their collaboration with Intelsius, combining our ORCA Multi-Use packaging with their data monitoring solutions.

We have a range of these solutions, including ORCA Connect, ORCA Single Use, and BioTherm. We’re also lucky to partner with expert data logger manufacturers, who we collaborate with to create the very best in connected temperature-controlled packaging. You can read more about our expert data logger partners on our dedicated webpage here.

You can view all our connected (IoT) solutions on our dedicated webpage here.

ORCA Cloud

ORCA Cloud allows you to track and report on multiple loggers in one place, simplifying the supply chain tracking process and giving you complete visibility of your payload without needing to access multiple portals.

No matter what packaging you use or which logger device you’re working with, you can monitor your payload throughout its journey and download reports all in one place.

ORCA Cloud allows you to live monitor key data such as:

- GPS location

- Temperature

- Humidity

- Device battery

- Device orientation

- Pressure

- Packaging open/close data

And, at the end of your payload’s journey you can access a suite of in-depth reports detailing the above data fields from the start of the journey, to the end. Click the button below to find out how ORCA Cloud can support your connected cold chain.

Get in Touch

We’d love to hear from you. If you have any questions about the Internet of Things, our connected solutions and data loggers, or how you can optimise your cold chain with connected solutions, get in touch with a dedicated team member.