Virtual Testing Services

Intelsius Virtual Testing Services, known as Atmospheric Thermal Modelling Services (ATMOS), form an integral part of the development of temperature-controlled packaging systems and provides comprehensive and meaningful simulation data to support and accelerate the development and qualification processes.

This would not be possible using only physical testing in climate chambers or test shipments – test shipments that cost more money and do unnecessary damage to the environment.

ATMOS is part of the Intelsius packaging development and qualification process and an essential solution for the next decade of providing excellence in cold chain packaging solutions.

The infographic below highlights our virtual testing processes but for further information or to discuss your specific requirements please contact your local office.

Virtual Testing Services: ATMOS Packaging

ATMOS Packaging uses digital versions of thermal packaging solutions. It enables us to predict their thermal performance against any ambient temperature profile in a fraction of the time required for physical testing in a climatic test chamber.

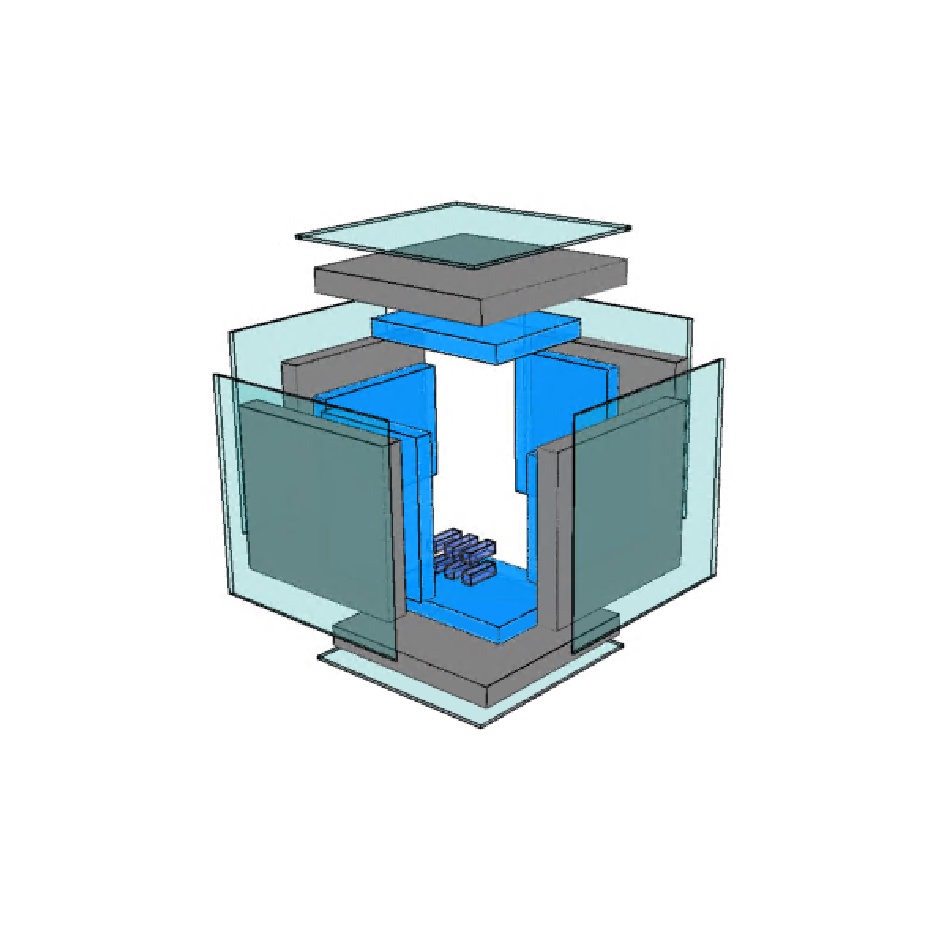

Our Virtual Testing Services produce a digital facsimile of a packaging system built. Its performance is calibrated to the thermal properties of the materials, insulation and coolants or PCMs of such packaging. A digital model of the packaging can now be used for virtual testing and performance predictions.

Intelsius has an extensive database of materials with all their thermal properties, including insulation, coolants and phase change materials (PCM), as well as a pre-built library of all Intelsius temperature-controlled packaging products. But also, third-party packaging solutions can be created, digitally tested and compared with ATMOS Packaging Services.

The simulation of physical, thermal tests gives us accurate predictions of how a system will behave under thermal stress in a fraction of the time and is the standard process for developing new thermal packaging solutions being developed at Intelsius.

These services can quickly develop an ideal packaging solution for our customers’ requirements and further optimize the packaging design.

ATMOS packaging models are also required for ATMOS Lane performance simulations and assessments.

Benefits of Using ATMOS Packaging

- Simulating Intelsius TCP systems with your payload against any temperature profile

- Compare Intelsius TCP systems for your payload to determine the ideal packaging for your application

- Development of tailored packaging solutions specifically designed for your requirements

- Reduced time scales when compared to thermal testing timelines in a climate chamber

- Create custom packing configurations or concepts.

Virtual Testing Services: ATMOS Lane

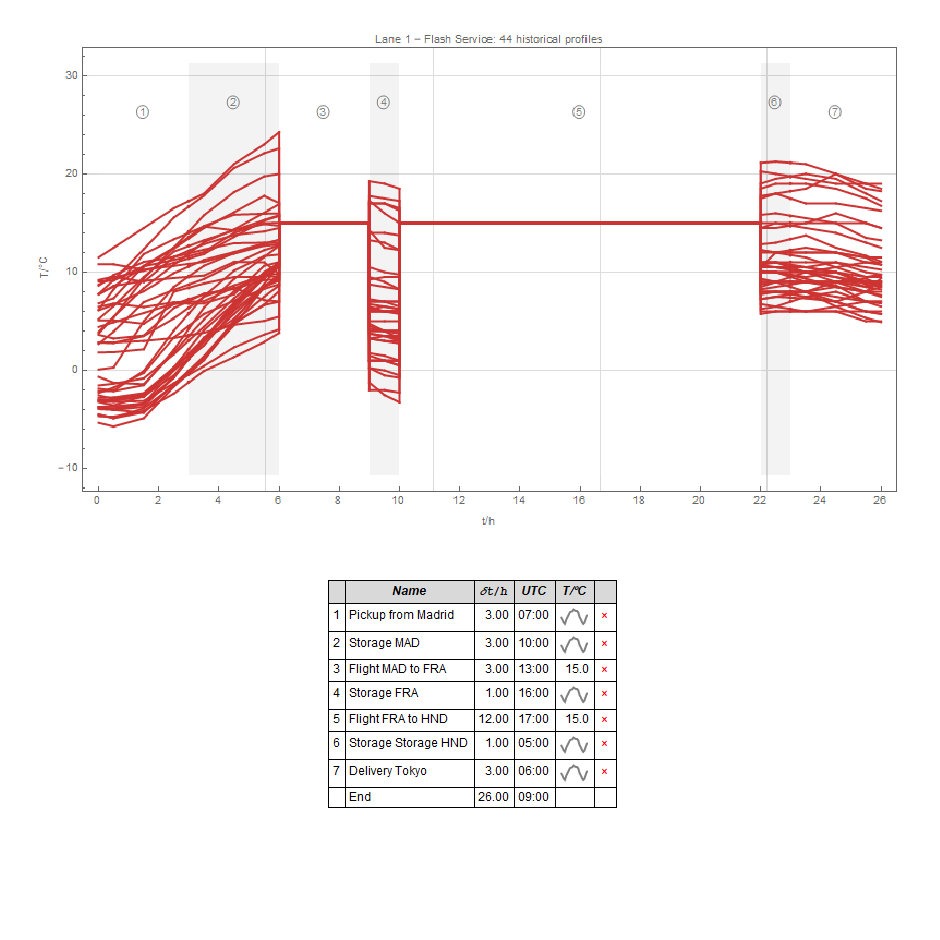

ATMOS Lane is an Intelsius Virtual Testing service that offers virtual performance assessments for thermal packaging that would not be possible based on physical test shipments alone. A digital facsimile of the packaging system is built, and its performance is calibrated to the thermal testing previously conducted.

ATMOS Lane utilises real-world temperature data, allowing us to predict the performance of a shipment before it’s been sent. Systems can be tested against the actual exposure temperatures experienced on a lane on any particular day of the year using historical data collected from weather stations worldwide. This can be repeated for as many days, months or years as required. This approach allows to simulate and predict the actual performance of a specific packaging system for thousands of year-round shipments in a matter of days.

This new virtual qualification service provides an unprecedented and super-fast packaging performance assessment not available through thermal testing in a climate chamber. In addition, the results allow us to demonstrate the real-life performance capabilities of the packaging system.

Benefits of Using ATMOS Lane

• Save cost and time compared to physical test shipments

• Simulate year-round shipping in a very short time

• Save high costs for large test shipment programs

• Simulate many shipments against real-world temperature profiles created directly from your shipping lanes

• Gain confidence in a shipment before it’s been sent

• Understand how to tailor packaging to fit your requirements

• Year-round virtual OQ testing in a matter of days instead of a month.