Physical Testing

Intelsius offer a wide range of physical testing services for parcel sized packaging solutions subject to special requirements or legal regulations.

We understand the importance of compliance in the movement of dangerous goods, pharmaceutical products, and the required rigorous testing. Therefore, Intelsius identifies the relevant test procedure suitable to demonstrate compliance for your packaging solution. Intelsius then develops the appropriate protocol for accurate setup, testing and reporting for your packaging.

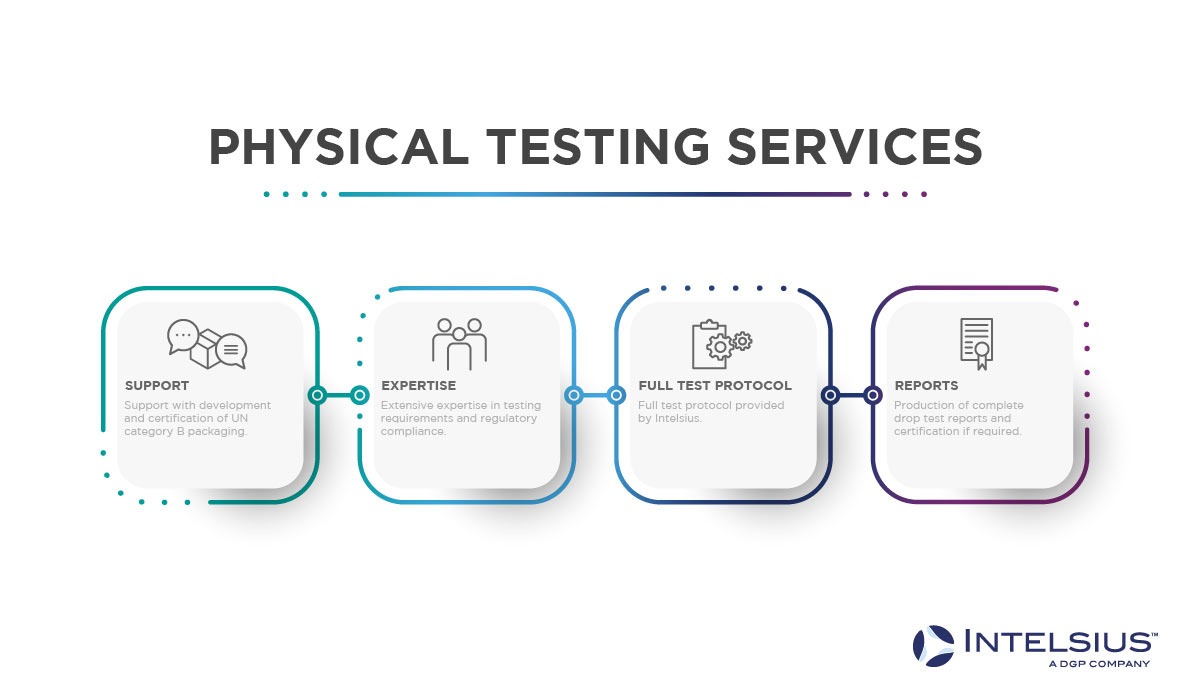

The infographic below highlights our physical testing processes but for further information or to discuss your specific requirements please contact your local office.

Class 6.2 Dangerous Goods Packaging Testing

Intelsius has the facilities and know-how to design, develop, and validate packaging for the transportation of UN3373 biological substances (Category B ), Exempt Specimens, and Limited Quantities to meet IATA, DGR, and ADR requirements and DOT CFR49 packing instructions 650 (PI650).

With our background in dangerous goods packaging and access to 100s of off the shelf components, we can design, develop and deliver a compliant packaging solution to meet your needs.

The testing requirements for PI 650 are typically a series of drops in different orientations, with variations in preparation conditions that are dependent on the materials of the external and primary packaging and the intended temperatures that the packaging will encounter during shipping.

As part of our facilities, we can also verify the performance of secondary pressure vessels (flexible and rigid) to ensure that these receptacles can meet the required pressure standards.

Intelsius can also assist with development testing for UN2900 and UN2814 Category A Infectious Substances before submitting packaging systems to a certified/accredited laboratory for approval testing to give you confidence that the developed systems are capable of meeting the regulatory requirements.

You can read more about shipping Category A and B Substances in our helpful guide here.

Benefits Of Having Your Transport Testing Carried Out By Intelsius

- Extensive expertise in testing requirements and regulatory compliance

- Guidance on system builds and payloads to help increase pass rates

- Full test protocol provided by Intelsius

- Production of complete drop test reports and certification if required

- Design, develop and qualify your packaging all under one roof.