What is Last Mile Delivery?

The last mile refers to the last leg of a product’s journey from the time it arrives at the final transportation location to before it reaches the hands of the end-user. Along the pharmaceutical cold chain, last mile delivery and logistics would involve the transport of various biologics like blood and tissue samples, vaccines, human specimen samples and other temperature-sensitive products which must be kept within a specific temperature range until it reaches its final destination.

Typically, the last mile is the most challenging and complex part of a pharmaceutical payload’s journey due to factors like infrastructural difficulties, inadequate transport links, variable humidity, temperature, shock and light, all of which can affect the integrity and efficacy of the payload’s contents. Thus, the challenge of temperature-sensitive last mile logistics is securing transport and storage solutions that are temperature-controlled.

This article discusses some of the main challenges of last mile delivery and how these challenges can be addressed and mitigated.

Challenges of Last Mile Delivery

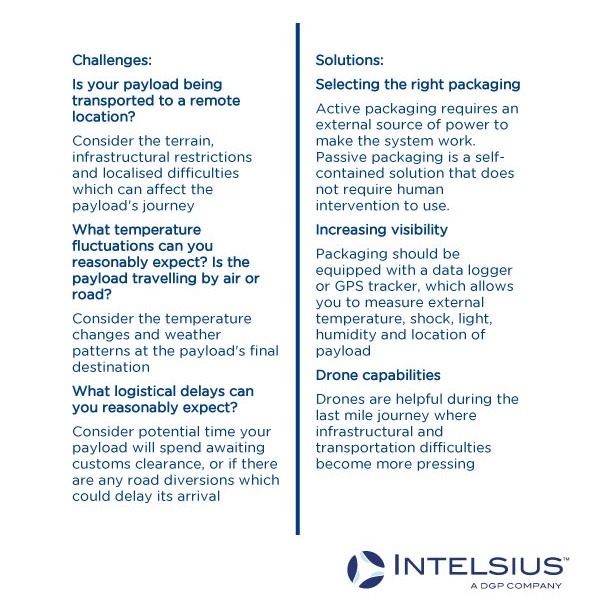

Below we have highlighted some key challenges faced during the last mile delivery stage. It is important to bear in mind that logistics providers play a crucial role to the success of delivery. The efficacy of logistics providers can vary greatly depending on which part of the world you are transporting pharmaceutical products from, as well as if these logistics providers are equipped to safely transport temperature-sensitive samples and products. Before organising logistics for your payload transport, ask yourself the following questions:

- Is your payload being transported to a remote location?

Transporting pharmaceutical goods to remote locations can be tricky, especially when the product requires temperature control to maintain efficacy. The journey from the last transportation hub to the patient can end up being hundreds of miles, across different locations, terrains and even weather. A lack of proper infrastructure and transportation facilities in remote locations could make it difficult for the payload to reach its destination without significant temperature excursions. An example would be the transport of vaccines during the Covid-19 pandemic, which had to be shipped all over the world including remote locations in unpredictable weather and temperature fluctuations.

- What temperature fluctuations can you reasonably expect?

One of the most crucial considerations when transporting temperature-sensitive payloads is the need to protect against fluctuations in temperature, as far as possible. The last mile journey will likely involve changes in external temperature if it’s travelling by air or road; for example if the payload is being transferred from inside to outside a designated cargo area, where temperatures are likely to change significantly. What kind of climate is expected at the payload’s destination and along the journey? Is your payload going to be adequately protected throughout these external temperature fluctuations?

- What delays can you reasonably expect?

When travelling along the cold chain be it via road or air, delays are inevitable. Your payload may be stuck in customs at its destination, awaiting clearance. Or there could be road diversions which prevent it from reaching its final destination on time, thereby risking further temperature excursions if left in inappropriate conditions for too long. Infrastructural difficulties or lack of adequate transportation facilities are also key considerations. How can you best mitigate these potential delays by selecting packaging and logistics services that can accommodate these potential delays and their effect on your payload?

Strategies for optimisation

- Selecting the right packaging

Choosing the right packaging with the required insulation is crucial for the last mile journey. You could select either active or passive packaging options, depending on various factors such as the length of the payload’s journey, the initial cost of purchasing the packaging, the level of temperature protection required, the need for power supply and the conditions of the external environment it is being transported through. We have highlighted the difference between the two systems in an article here, along with other key considerations, if you are unsure of which option to select.

Active packaging (such as reefer trucks) requires an external source of power to make the system work. Passive packaging, on the other hand, is a self-contained solution that does not require human intervention; it is a pre-conditioned solution that is ready for use. Another key consideration for the last mile journey is the unique infrastructural and localised difficulties that it can present, on top of issues like power cuts, or even human error. One way to mitigate these risks is having a self-contained passive packaging system that can offer thermal protection without the need for external intervention or manipulation.

- Increasing visibility

Besides selecting the right packaging and logistics services, it is crucial to have tracking capabilities by way of a data logger, or GPS tracker, which gives you the ability to monitor your payload throughout its journey to measure external temperature, shock, light, humidity and related factors which affect the shipment. For example, ORCA Connect has tracking capabilities and is compatible with a wide range of data loggers to keep you connected to your shipment at all times.

Such data is crucial to be able to track your payload to check if it is safe and within the acceptable temperature and surrounding conditions End-to-end visibility along the cold chain is a key way to mitigate the risks and challenges that come with last mile delivery.

- Drone capabilities

While still in its infant stages of global implementation, drone deliveries are gaining traction on a larger scale due to its speed, efficiency and potential cost-effectiveness. They can be particularly helpful during the last mile journey where infrastructural difficulties become more pressing. While it may take time before commercial drone deliveries become the go-to delivery mode, it is expected to be a disruptor of last mile delivery because of its ability to meet a range of consumer needs, such as transporting life-saving chemotherapy treatment.

Intelsius is involved in a drone flight project known as Project Caelus, aimed at developing a virtual model of the first ever national medical distribution network in the UK using drones. The Project is a consortium of 16 members and is aimed at developing a virtual model of the proposed medical distribution network which will facilitate the transport of medication, organs, blood samples and other medical supplies throughout Scotland. The delivery network will connect hospitals, pathology laboratories, distribution centres and GP surgeries across the country to allow for better access to essential medical supplies for urban and rural remote areas. You can read more about Project Caelus here.

Intelsius Passive Packaging Solutions

As a designer and manufacturer of passive temperature-controlled packaging solutions for over 25 years, we have created a range of packaging systems that cater to all requirements of your payload. ORCA temperature-controlled packaging solutions offer you the highest performance in temperature control as they utilise phase change materials (PCM) and vacuum insulated panelling (VIP) which provide superior insulation for your payload for up to 120 hours.

The PharmaTherm range utilises expanded polystyrene for a lightweight solution that offers up to 120 hours of thermal protection. Both product ranges have multiple temperature profiles from ambient to refrigerated, as well as frozen with dry ice. For tracking capabilities, we carry a range of temperature loggers to help you track the status of your payload during its journey.

Conclusion

The last mile delivery along the pharmaceutical cold chain presents challenges that are unique to local conditions. Despite being the most complex part of the shipment journey, these challenges can be overcome paying special attention to the potential difficulties your payload will encounter along the way and mitigating those challenges by using the right packaging and tracking facilities to increase end-to-end visibility.

Get in Touch

If you would like to know more about how we can support your last mile delivery or to find out more about our temperature-controlled solutions, reach out to cs@intelsius.com and our customer service representatives will be happy to assist you.