As the global supply chain becomes more expensive, more exposed to risk, and in need of more sustainable solutions to help us achieve our collective net-zero carbon emissions targets, it’s essential that you partner with like-minded organisations with tangible solutions in place to meet these challenges.

The worldwide pharmaceutical market is set to grow at about 5.8% over the next five years, to be worth about USD 1.5 trillion by 2028. The industry is constantly evolving, particularly after the effects of COVID-19 on cold supply chains worldwide. The need for robust, safe, qualified and sustainable cold chain packaging solutions has become more important than ever. This is where Intelsius’ global manufacturing strategy best serves its customers.

We sat down with the Co-Founder and CEO of Intelsius, David P. Walsh, to ask him about the organisation’s global manufacturing presence and how this impacts cost and risk for our customers and how it helps to reduce your carbon footprint.

how this impacts cost and risk for our customers and how it helps to reduce your carbon footprint.

Where are Intelsius’ manufacturing sites currently?

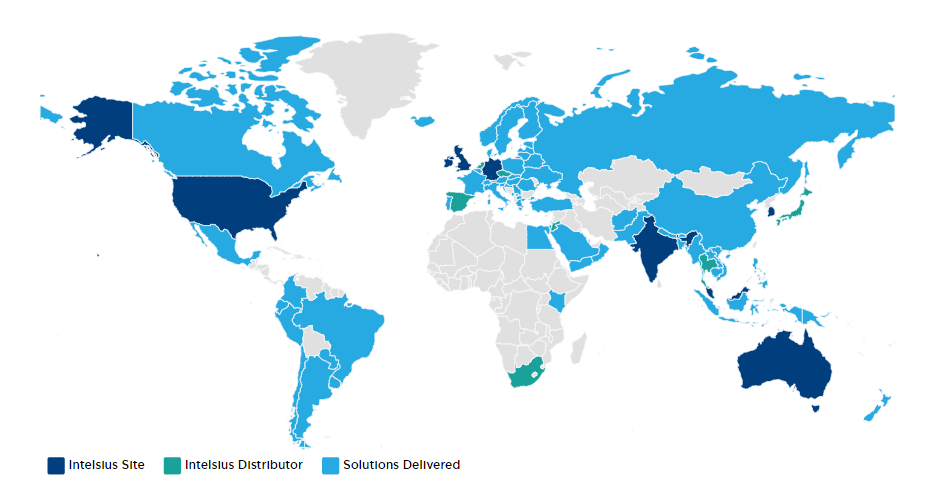

We currently have six manufacturing sites and are one of the few cold chain packaging providers present in strategic locations in the EU, the US and Asia. In the EU, we have our headquarters site in York, United Kingdom, a German site in Frankfurt and a site in Killarney, Ireland. All of these offices supply our entire range of sample transport and temperature—controlled packaging solutions. Our German office is strategically situated near Frankfurt airport, able to deliver products to the continental EU within 24 hours, and can provide expert Technical services for the entire DACH region. Our US office, located in Indianapolis, serves the North and South American regions, with the ability to deliver same-day, direct-to-site fulfilment on orders.

We have a site in Mumbai, India, which serves the entirety of the Indian market, and another site just outside Perak, Malaysia, which can serve China, Korea, Indonesia, Singapore, Thailand, Vietnam and the rest of the surrounding Asia Pacific region with our full range of STP and TCP solutions.

We had always intended to be a global business when we began operations over 20 years ago. Driven by the presence of good opportunities in the regions we entered, we were strategic about selecting locations which would be most beneficial to our customers and to the business. We began our foray into packaging by providing sample transport packaging solutions for clinical trials and by designing specialist UN3373-compliant packaging, which was used during the Bovine Spongiform Encephalitis, or “Mad Cow Disease” outbreak. Along the way, we realised there was a need for effective temperature-controlled packaging solutions and ventured first into providing dry ice systems for our customers. From there, our product offering expanded to the full range of both STP and TCP packaging solutions which we offer today.

Our global manufacturing strategy has grown in tandem with demand for our products and solutions. We take steps to uphold a high global standard of quality for all our solutions, which means all our manufacturing processes are closely adhered to and vetted.

How does our global presence affect cost control measures for our customers?

Multiple manufacturing sites mean cost-positive effects for our customers because we can ship our solutions from more than one location – thereby reducing associated transport and shipping costs. The technology used for our solutions is transferred over to the other locations without compromising the quality of our systems. The cost-benefit to the customers is that they have locally manufactured or assembled systems on their doorstep, so it takes the issue of cost of distribution out of the equation, whether it’s by air or sea freight or other means.

This is especially important during times of global uncertainty and price hikes such as those that occurred due to COVID-19, where container freight prices soared to nearly US$10,400 in September 2021, an increase of 320% from the same period of the previous year. In such times, customers benefit from having a local manufacturer or distributor directly shipping solutions within the same country or region.

Besides our manufacturing sites, we also have distributors and agents in 13 locations across the globe, which can provide a wide range of our TCP and STP solutions to our customers. The network of distributors allows us to reach our customers in other parts of the world while still ensuring the highest quality of products and reducing shipping, transport and storage costs.

How does our global presence mitigate risks in the supply chain?

Having multiple manufacturing sites around the world gives us built-in redundancy, where if one site cannot operate, the others could step in to fill the gaps and meet the needs of our customers. Having manufacturing capabilities in multiple regions and continents allows us the flexibility to mitigate risks and have various contingency plans in place, such as in the occurrence of a natural disaster or a global pandemic. This was especially apparent during the COVID-19 movement lockdowns imposed worldwide, which hugely affected production and compromised supply chains.

Another example of a need for risk mitigation was seen in 2011, when huge portions of automotive supply chains around the world were cut off after a devastating earthquake occurred in Japan, effectively halting carmaker Toyota’s production. The event forced the automaker to rework its risk management strategies. Regionalizing manufacturing with local sourcing and distribution, therefore, helps to mitigate such risks by ensuring that supplies are not concentrated at one location or source.

Intelsius’ manufacturing strategy was extremely effective during the pandemic, when our Malaysian site was shut down due to government-imposed lockdowns and our German, US and UK sites stepped in to successfully meet our Asia Pacific customers’ needs.

How does Intelsius’ global manufacturing strategy influence its environmental sustainability efforts?

Having several manufacturing sites in strategic regional locations shortens the supply chain and eliminates the need for shipping and transport over very long distances, which reduces the associated carbon emissions. With 60% of all global emissions being generated by supply chains, the key to climate change is in shortening the supply chain by ensuring regional manufacturing and distribution.

The local communities will see the most significant benefit from our global manufacturing and distribution footprint; for example, our distributor in Spain deployed our ORCA range of solutions to transport COVID-19 vaccines in the country during the pandemic. We also have distributors in the Netherlands, Japan, South Korea, Jordan, Israel, Thailand and Australia to serve the local communities in those locations with a range of both our STP and TCP solutions.

Additionally, if our customers are unable to source our products directly from our offices or distributors, our agents in Malaysia, Hong Kong, Shanghai, and Singapore can serve our customers in those locations.

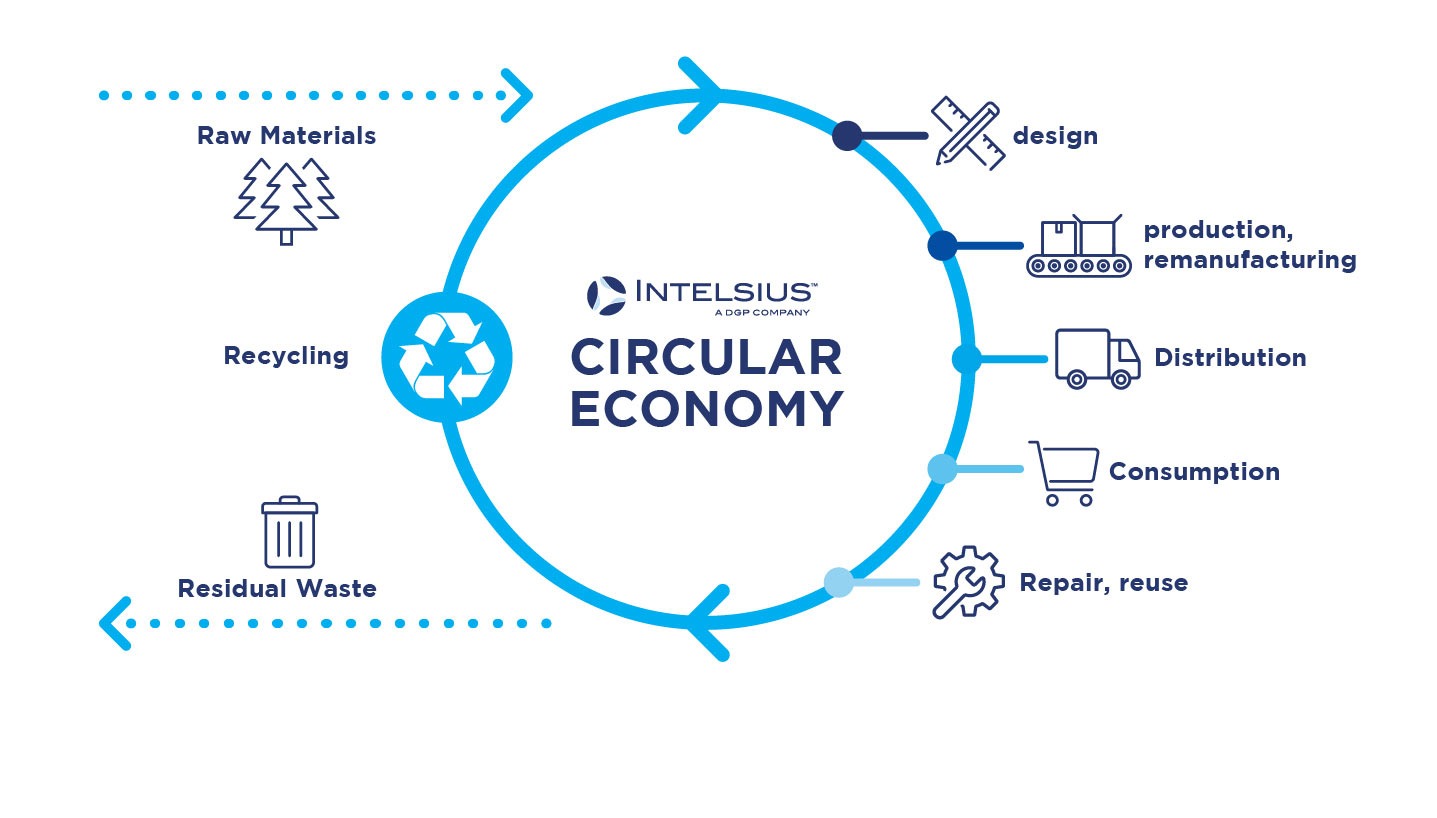

We also have an ambitious Net Zero Strategy, and we are working hard to ensure our products are as sustainable and environmentally friendly as possible without compromising quality. As a business, we are prioritising the transition to a more circular economy by providing customers with rental options like our ORCA Rental or a reusable option like ORCA Multi-Use to keep our products in circulation and out of landfills as far as possible.

What solutions do Intelsius offer?

We offer a wide range of TCP and STP solutions, catering to specific and bespoke requirements. Our TCP range offers ISTA-certified, specially designed, tested and qualified solutions for your pharmaceutical or biopharmaceutical needs. Our TCP range covers ambient (15°C to 25°C), cold (2°C to 8°C), frozen (-15°C to -25°C) and dry ice options with sizes ranging from a 1L handheld to 345L pallet-sized shippers to meet any of your temperature-controlled sample needs. We also have our high-performance ORCA range, which utilises Vacuum Insulated Panel (VIP) technology combined with advanced phase change materials to offer the highest level of protection for temperature-sensitive payloads. Our connected packaging options are available in various sizes to ensure the highest visibility for your payload. You can explore the full range of our TCP solutions here.

Meanwhile, our STP solutions cover a broad scope of Category A and Category B compliant packaging for all your dangerous goods requirements, the full range of which can be found here. Besides these options, we also offer bespoke kitting services to combine primary, secondary and tertiary packaging to meet any specific requirements you may have. For example, we provide specialist UN3373 Category B packaging and bespoke refurbishment solutions for our logistics partner, DX, for use in their tracked specimen service. You can read our case study about our collaboration here.

Get in Touch

If you would like to know more about our range of STP and TCP solutions or more about our rental and reusable packaging, please contact our knowledgeable customer service representatives in any of the locations mentioned above. Contact details for all offices, distributors and agents can be found here.

You can also purchase our solutions online on our UK, German and US websites, however if you require any additional assistance or if you are unsure which office or distributor to contact for your location, reach out to compliance@intelsius.com and we will help you with your specific requirements.

External Sources:

- https://www.statista.com/outlook/hmo/pharmaceuticals/worldwide

- https://www.statista.com/statistics/1250636/global-container-freight-index/

- https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Impact_of_Covid-19_crisis_on_industrial_production#:~:text=Within%20only%20two%20months%2C%20between,by%20more%20than%2040%20points.

- https://www2.deloitte.com/content/dam/Deloitte/de/Documents/financial-services/Deloitte-location%20decision%20of%20Shared%20Service%20Centers.pdf

- https://www.reuters.com/article/us-japan-quake-supplychain-idUSKCN0WW09N

- https://www.accenture.com/gb-en/insights/supply-chain-operations/supply-chains-key-unlocking-net-zero-emissions