What is a circular economy; how can you adopt a circular economy in your working practices, and how could it benefit both the natural environment and your budget? These are just some of the questions being asked as companies seek green solutions to existing production methods.

Before delving into the detail, it is important to understand what forces are driving change for businesses and business leaders worldwide. The Paris Agreement (also known as the Paris Climate Agreement) provides a solid foundation from which to start.

What is the Paris Agreement?

If you work in logistics, manufacture a product, or provide a service, you’ll be aware of the increasing demand for more environmentally sustainable solutions. These demands most likely come from your customers, who are themselves are trying to lead greener, more environmentally friendly lifestyles or meet their own internal corporate responsibility targets. You’ll also be aware of certain commitments made by your Government, which, depending on what country you live and work in, could even include a legal requirement to meet a certain, reduced level of carbon emissions by a particular date.

In 2015 at the Paris Climate Change Conference (COP 21), 196 countries signed a legally binding agreement to limit global warming to well below 2, preferably 1.5 degrees Celsius, compared to pre-industrial (1850 – 1900) levels. This legally binding agreement became known as the Paris Agreement or Paris Climate Agreement. It was then up to those 196 countries to devise their own plans to help achieve this collective goal. For example, in the U.K., the Government has committed itself to achieving net zero by 2050, meaning businesses will be required by law to meet this expectation over the next three decades.1

Achieving Carbon Neutrality

The U.K. and U.S. governments have committed to achieving net-zero carbon emissions by 2050. In Germany, this target is slated for 2045, and in India, they’ve set a target for carbon neutrality by 2075. Net-zero commitments have sharpened the focus of businesses wold over who are now being challenged to find green alternatives. However, like many businesses, Intelsius had already begun to deliver more sustainable practices and products before these targets were set.

For many, reducing carbon or ‘offsetting’ carbon emissions have followed traditional paths such as recycling waste, fitting LED lights, or investing in offsetting programmes such as tree planting or environmental cleanup schemes. This work has and will continue to be an essential part of achieving net-zero. In addition, however, there is a growing move towards something called a circular economy. As a result, the old mantra of ‘take-make-waste’ is being challenged and replaced by a culture of refurbishment and reusability.

What is a Circular Economy?

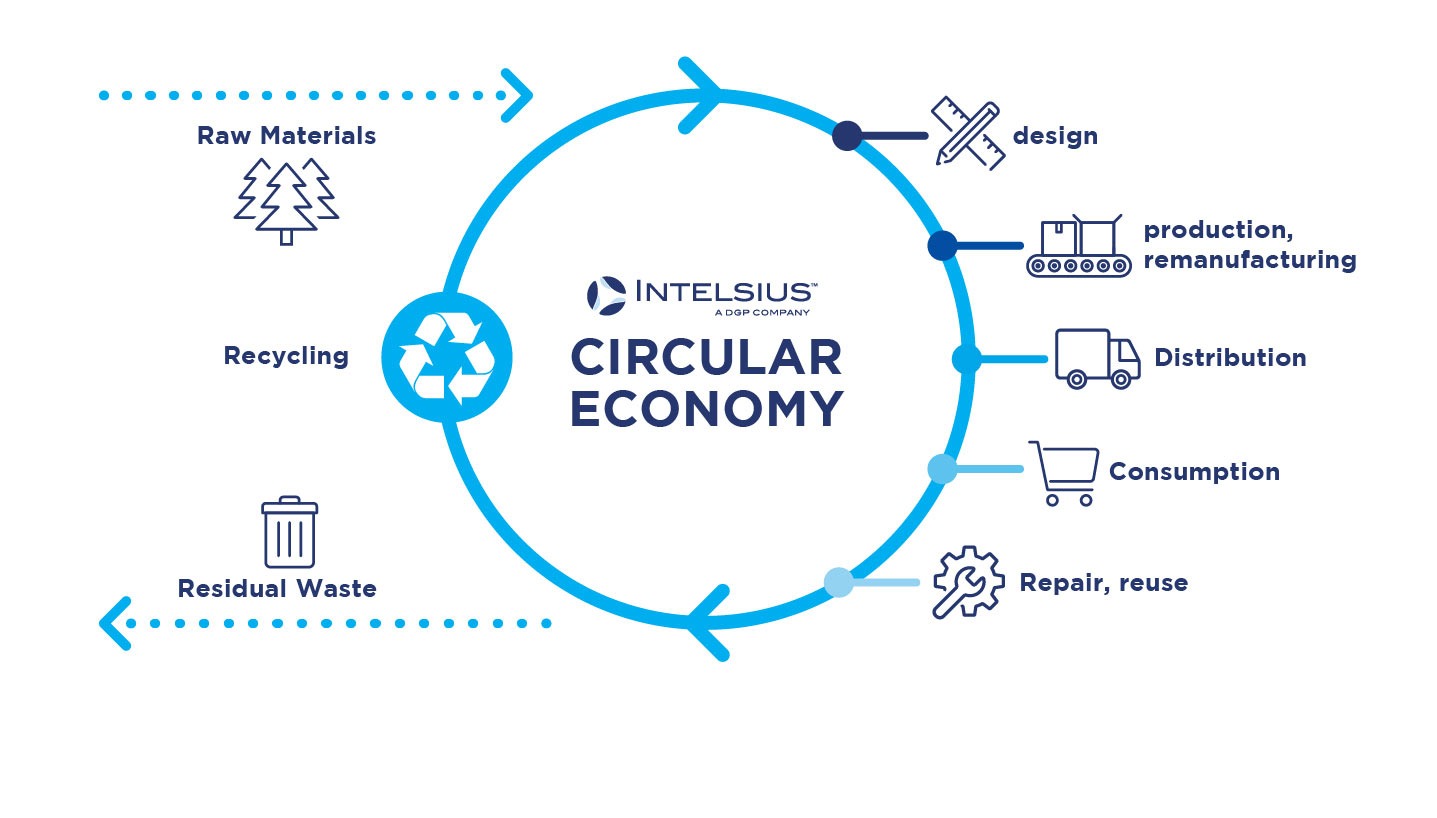

If the traditional, linear economy follows a ‘take-make-waste’ methodology that harvests non-renewable resources, uses those resources in a high-carbon producing production process and then sells them to consumers who will ultimately discard the product in landfills, a circular economy provides an environmentally and economically responsible alternative.

In short, a circular economy uses more sustainable resources, keeps those resources in use for longer, and when the product’s life cycle is complete, it’s recycled or used to regenerate the natural environment. Looking in more detail, the circular economy can be broken down into three core elements:

- Designing out waste and pollution

- Keeping products and materials in use

- Regenerating natural systems

1. Designing out Waste and Pollution

Designing out waste and pollution is what it says on the tin: we need to start designing products in a way that eliminates needless use of non-renewables and high-carbon production processes. That means looking at alternative resources for products that, until now, have mainly or exclusively used non-renewable resources. It also means looking at our production practices and finding ways to reduce our carbon emissions and energy use.

Burger King, Nike and IKEA are just some of the big-name brands adopting circular economy product lines, allowing consumers to buy recycled versions of their favourite products and then return packaging, or the product itself when they’re ready, allowing it to be refurbished and resold.

Another big brand tackling the issue of reliance on non-renewables are Adidas, who have designed their UltraBoost DNA Loop shoes using just one material – thermoplastic polyurethane (TPU). This reusable material is also recyclable and fully biodegrades in between 3 and 5 years.2

The circular economy of the shoe is in the name, ‘Loop’, with Adidas adopting the tagline, ‘made to be remade’, focusing on the fact that once worn out, shoes can be returned to Adidas to be remade into new Loop trainers, thus keeping the materials in use for longer.

2. Keeping Products and Materials in Use

Whereas designing out waste (using renewable resources and low-carbon production) and regenerating the natural system (composting, for example) are fairly well-established parts of corporate green strategies, keeping products and materials in use isn’t and represents a huge stride towards truly sustainable production practices.

Using an earlier example, IKEA now offers a ‘buyback and resell’ service that incentivises customers to sell their old IKEA furniture back to IKEA, who will then refurbish it and resell it to a new customer. This is a perfect example of keeping products and materials in use, increasing the lifespan of valuable resources, and in theory, could see the same materials recycled over and over again indefinitely.

Burger King is also offering customers at certain branches the chance to buy products in reuseable packaging, charging them a small deposit, which will then be returned to them when they return their packaging. Burger King will then clean the packaging, and use it again, thus extending its life cycle.

3. Regenerating Natural Systems

Regenerating natural systems isn’t just about recycling or avoiding landfill waste but actively enhancing our natural environment by returning natural resources to the surrounding ecosystem, or working with organisations who positively impact the natural environment. It’s estimated that land degradation costs $40 billion worldwide each year, not accounting for hidden costs such as increased fertiliser use, loss of biodiversity and unique landscapes.3

By returning biological materials into the ecosystem, we not only cut emissions but regenerate the surrounding environment while saving money. However, for many companies, this final step could present the toughest to get right and requires a lot of thought about the kind of materials being used in production.

There are numerous companies operating regeneration schemes, actively improving their natural environment by eliminating landfill waste. A leading example of this approach is Unilever, a global consumer goods giant responsible for manufacturing hundreds of household items. Their Regenerating Nature programme aims to not only use less and recycle more, but to actively improve soil, farmlands, the longevity of crops, and the wider natural eco-system.

You can read more about Unilever’s approach to environmental regeneration here.

ORCA Rental: Circular Economy Cold Chain Packaging

As outlined in Our Green Mission, we think long and hard about delivering greener products and working practices. This means recycling 100% of cardboard waste, installing energy-efficient light systems, and, where possible, using recyclable materials in our products. At our Frankfurt-based German site, we’re incredibly proud to generate 100% of our electricity from renewable resources, including biogas, wind, solar and water. We also work closely with two incredible environmental charities, One Tree Planted and the ORCA Charity, as we look to give back to our natural environment, planting trees and regenerating our natural environment.

But it’s our ORCA Rental services that most closely resemble a circular economy, allowing customers to rent packaging for a specific time period and delivery need, and then return it to us for cleaning and refurbishment once they’ve completed their delivery. This service allows us to keep our rental packaging in the supply chain indefinitely, maximising efficiency and eliminating landfill waste.

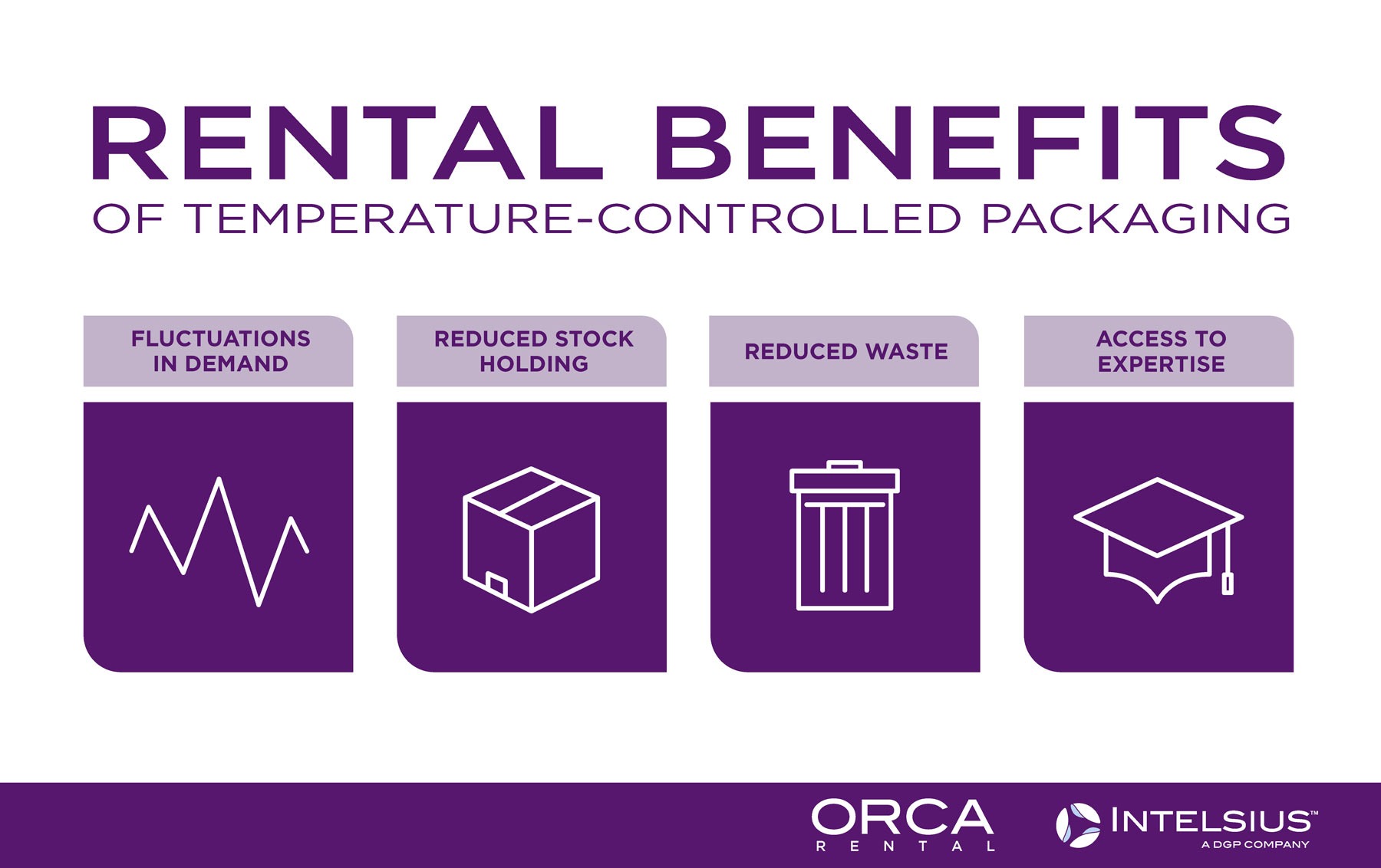

The benefits of ORCA Rental go beyond your carbon footprint, however. By using rented cold chain packaging, you can react to fluctuations in demand without investing in owned stock. This frees up space, saves you money, and all while saving the planet.

You can find out more about ORCA Rental, and how it can reduce your carbon footprint and save you money by clicking the button below.

Or, to speak to a member of our dedicated team about ORCA Rental, Our Green Mission, or any of our products or services, click the button below.

External Resources

- United Nations (2015) – The Paris Agreement

- World Economic Forum (2021) – Circular Economy Examples

- Ellen Macarthur Foundation (2021) – The Circular Economy in Detail

- Unilever (2021) – Regenerating Nature