The pharmaceutical cold chain is responsible for the safe transport of drugs, vaccines and biological samples worldwide. A lesser-known impact of the pharmaceutical cold chain is its effect on the environment. This article will examine the impact the pharmaceutical cold chain has on carbon emissions and the next steps we can take to ensure pharmaceutical drug efficacy while protecting our environment.

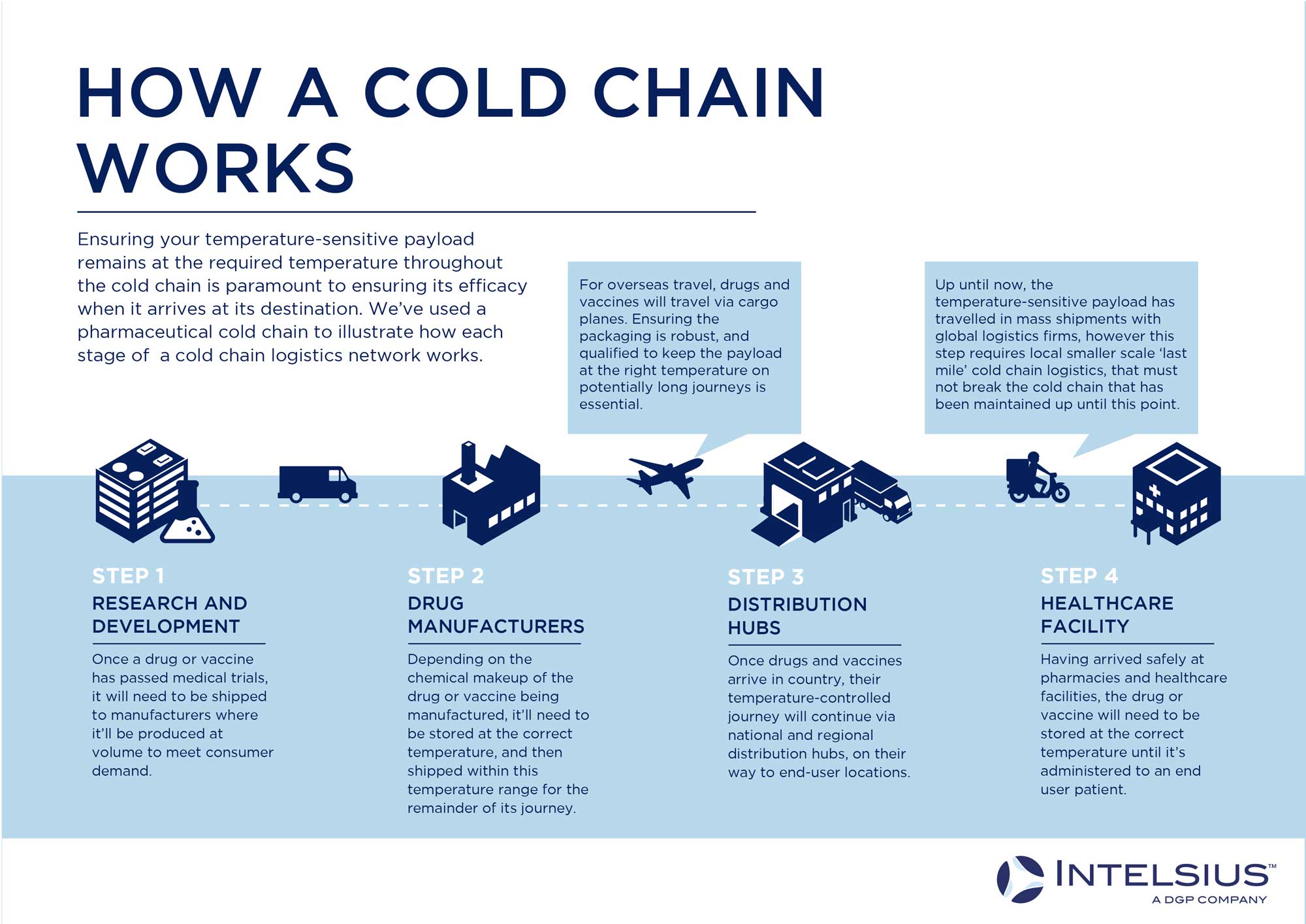

How does the pharmaceutical cold chain work?

The pharmaceutical cold chain involves storing and transporting drugs, biological substances, vaccines and other medications within a specific temperature range to maintain their efficacy and safety.

An unbroken cold chain is essential to ensuring patient health and safety as temperature-sensitive drugs are transported around the world. The need to maintain specific temperatures throughout a shipment presents specialised challenges when ensuring the efficacy and safety of a drug are not compromised. The cold chain process is often complex and involves many moving parts, and all parties must be vigilant to ensure there is no break in the chain.

The first step of the process involves the research and development of a drug or vaccine, followed by clinical trials and subsequent approvals. The drug is then sent for manufacturing, after which its temperature-controlled journey begins. The drug is then stored at the country’s national and regional distribution hubs before being delivered to the relevant healthcare facilities or the end-user.

What are greenhouse gases, and what is their effect on the environment?

Greenhouse gases like carbon dioxide (CO2) methane, nitrous oxide and fluorinated gases are emitted during the production of coal, natural gas and oil, as well as agricultural activities such as farming, livestock and decaying landfills.

Greenhouse gases are bad for the environment because they trap the Sun’s heat in the Earth’s atmosphere, like a blanket, increasing the Earth’s overall temperature – which in turn causes changes in weather patterns and rising sea levels. Carbon dioxide forms a large portion of the greenhouse gases emitted through human activities like burning fossil fuels (coal, natural gas and oil) to generate electricity, power transportation, and facilitate industrial processes.

What are carbon emission rates for the pharmaceutical cold chain?

A Green Paper created by Health Care Without Harm and ARUP revealed that the global healthcare industry is responsible for 4.4% of total global carbon emissions, amounting to two gigatons of carbon dioxide. The world’s top emitters are the United States, China and the European Union, which collectively total 75% of global healthcare emissions. Every country is responsible for both indirect and direct carbon emissions, with the majority (71%) of emissions coming from the production, transport and disposal of healthcare goods and services.

The pharmaceutical cold chain emits 55% more greenhouse gas emissions than the automotive sector. The pharmaceutical supply chain relies on fossil fuels, from warehousing and storage to transportation and delivery of temperature-sensitive goods. Additionally, manufacturing temperature-sensitive drugs and products consumes large amounts of energy, notwithstanding the transport, use and disposal of these products.

It has been estimated that 4 million refrigerated trucks, trailers, and vans are in operation worldwide, with 40% of the total fleet comprising vans, 30% trucks and 30% semi-trailers. 84% of the refrigerated road transport industry’s total fuel use is diesel, contributing to 35 % of all global transport-related greenhouse gas emissions.

Besides refrigerated transport, cold chain storage facilities also demand significant amounts of power and energy to run, as they need to be on 24 hours a day without stopping. In a standard refrigerated warehouse, approximately 15% of total energy is used to power components like pumps, motors, conveyors and fans.

Global net-zero targets

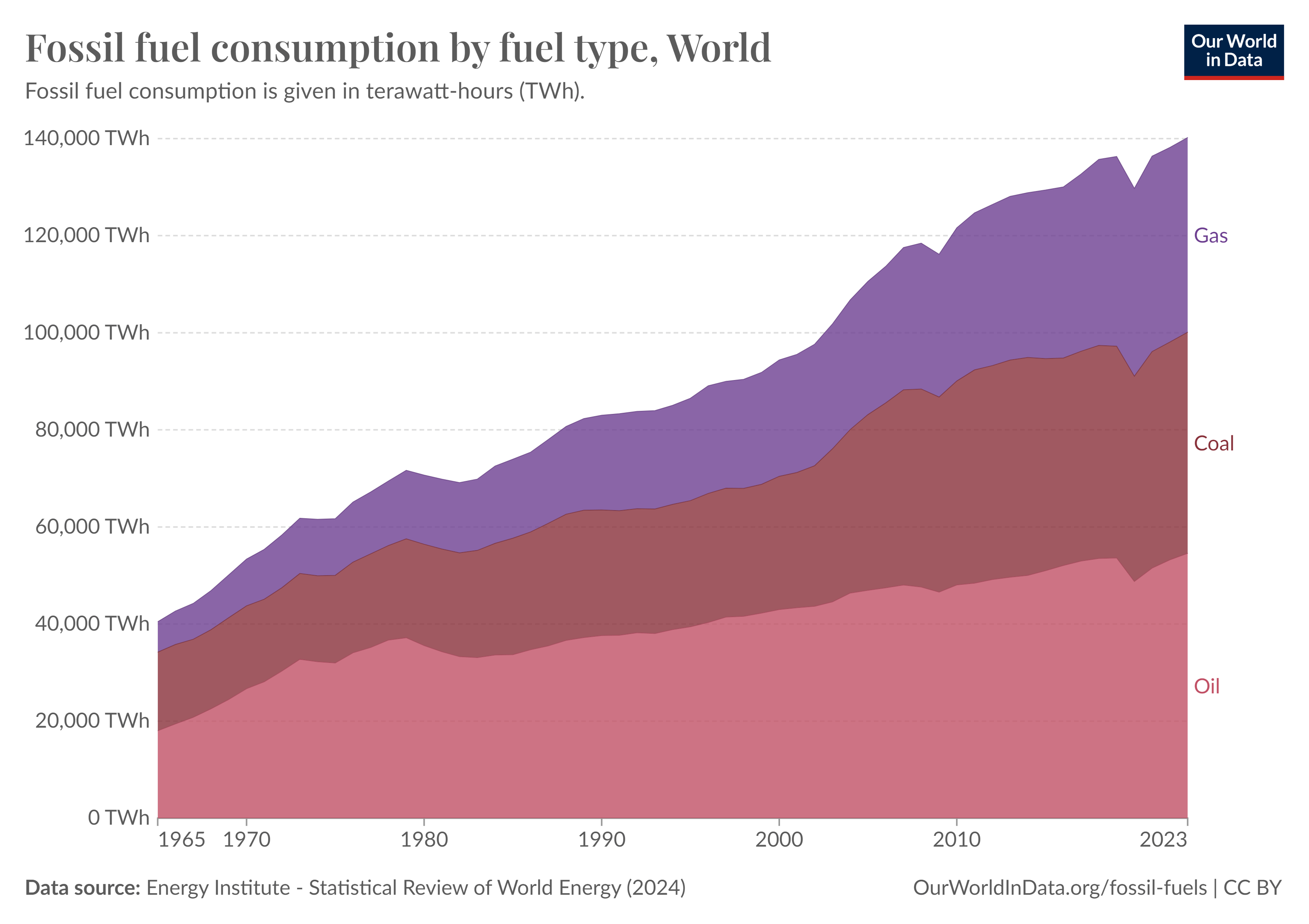

Fossil fuel consumption has more than tripled since 1965, signifying the immense reliance on carbon-intensive processes in production and transportation. If global carbon emissions are not mitigated significantly, scientists are predicting global temperatures to increase by 1.5°C in 2050 and between 2-4°C by 2100. This increase in temperature has adverse effects that are wide and far-reaching, such as the melting of glaciers and ice caps and unprecedented changes in weather patterns, to name a few.

The Paris Agreement is an international treaty on climate change, signed by 196 countries at the UN Climate Change Conference in 2015. The treaty aims to limit the increase in temperature of the globe to 1.5°C above pre-industrial levels (1850-1900). The legally binding treaty entered into force in November 2016 and marks the first agreement of its kind in which countries work together to fight the effects of climate change.

The United States and the European Union have set goals to achieve net-zero greenhouse gas emissions by 2050, while China’s goal is to reach it by 2060. While these ambitious targets have been set, a UN report has revealed that, as it stands, countries are not on track to reach the 1.5°C target unless an immediate system-wide transformation occurs.

In 2023, fossil fuels comprised 81.5% of the world’s primary energy despite an uptick in wind and solar power usage to generate electricity. In Europe, the share of fossil fuels dropped to below 70% of primary energy for the first time since the Industrial Revolution, driven by the development of renewable energy. Contrarily, fossil fuel consumption grew by 8% in India in 2023, marking the first time India surpassed Europe and North America in coal usage.

The role of a circular economy

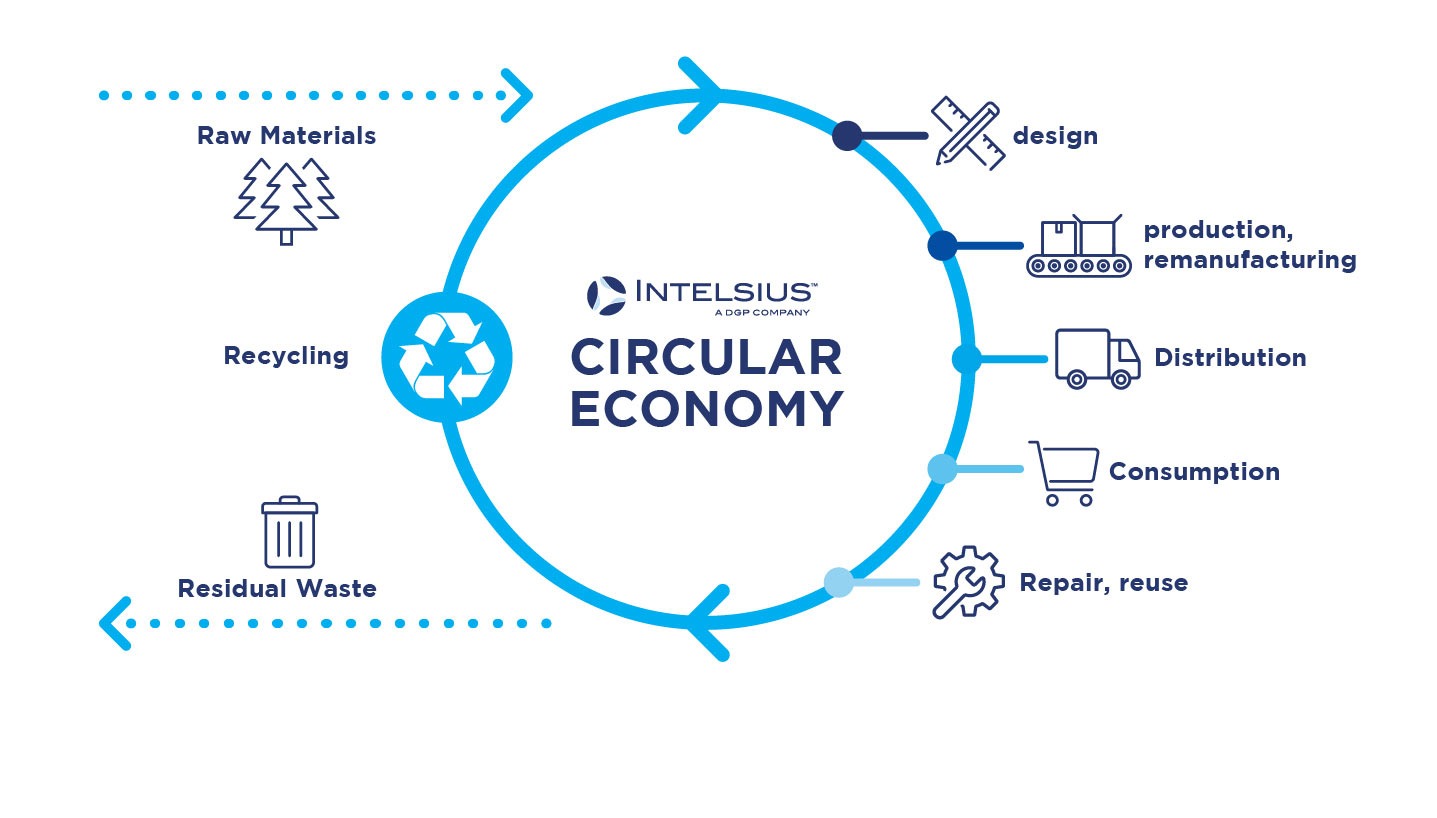

The circular economy involves keeping materials and products in use for as long as possible through recycling, refurbishing and reusing them to avoid them ending up in landfills. Conversely, the current linear economy approach involves a “take-make-waste” model that relies on sourcing non-renewable resources to be used in a carbon-intensive production process. You can read our blog on the circular economy here, which delves deeper into the specifics of this model of production.

Packaging is a good example of how a circular economy approach is effective. Manufacturing packaging using eco-friendly materials and ensuring that the manufacturing process is as energy efficient as possible is the starting point for preventing unnecessary product waste and conserving energy.

The circular economy approach has many benefits for the environment because it prioritises an environmentally friendly production process from start to finish. Beginning with sourcing renewable raw materials, carrying out production processes using energy-efficient methods, and finally (and most importantly) keeping the final product or its stripped-down parts in circulation for as long as possible. This last step in this process will be the most challenging to execute as it represents a big shift away from the current model of manufacturing and production.

To effectively implement the circular approach, manufacturers and service providers would need to provide customers with a way to recycle, refurbish or reuse the final product or its broken-down parts, ensuring that the materials remain in use or as long as possible or even indefinitely.

How to mitigate cold chain carbon emissions with packaging

Eco-friendly and reusable packaging

The pharmaceutical industry creates 300 million tonnes of plastic waste each year, half of which comes from single-use packaging solutions. The industry typically relies on single-use passive packaging or energy-intensive active packaging solutions to transport drugs and pharmaceuticals. This approach has led to huge amounts of waste ending up in landfills and a crippling reliance on carbon-intensive processes to manufacture and transport temperature-sensitive cargo. As industries are now looking for more environmentally-friendly solutions,

The way forward is to focus on the recyclability of the whole packaging system and to ensure that raw materials used in the manufacture of the packaging are from renewable sources and can be individually reused or recycled, in line with the circular economy model.

Reusable and eco-friendly packaging solutions by Intelsius

Intelsius offers a range of reusable and eco-friendly packaging solutions that can both serve your temperature-sensitive cargo needs and reduce your negative environmental impact.

ORCA Rental

The ORCA Range is a high-performance temperature-controlled packaging solution that is ideal for the safe and secure shipment of your payload. Available from the 1L ORCA Response size to our 345L pallet-sized packaging, solutions can be specifically tailored to your needs. The range utilises advanced phase change materials (PCM) and high-quality vacuum insulated panelling (VIP) to maintain temperature for up to 120 hours while in transit.

Our ORCA rental service allows you to rent any ORCA solutions, which can be tailored to your needs according to:

- Temperature

- Size

- Pre-conditioning

- Logger integrations

- Delivery legs

Watch our short video below on how ORCA Rental works:

ORCA Multi-Use

The ORCA Multi-Use range also utilises phase change material (PCM) and vacuum insulated panel (VIP) technology, ensuring that your high value payload is safe and secure until it reaches its final destination. The Multi-Use solution is designed to be used for up to 5 years before refurbishment or replacement is needed.

GreenTherm

Our newest product, the fully recyclable and eco-friendly GreenTherm solution, uses 70% recycled materials and paper-based cellulose insulation, offering high-performance temperature protection for up to 96 hours. The system is available in 3 sizes: 7L, 14L, and 23L and is Category B compliant.

The innovative design of GreenTherm allows you to recycle the solution within one paper waste recycling stream. The solution was designed with circularity in mind, ensuring that all materials can be recycled and reused to extend their shelf life.

Get in Touch

Reach out to us at cs@intelsius.com to find out more about how our eco-friendly packaging solutions can serve your cold chain needs, or if you’d like to know more about our Green Mission and Net Zero Strategy, click here.